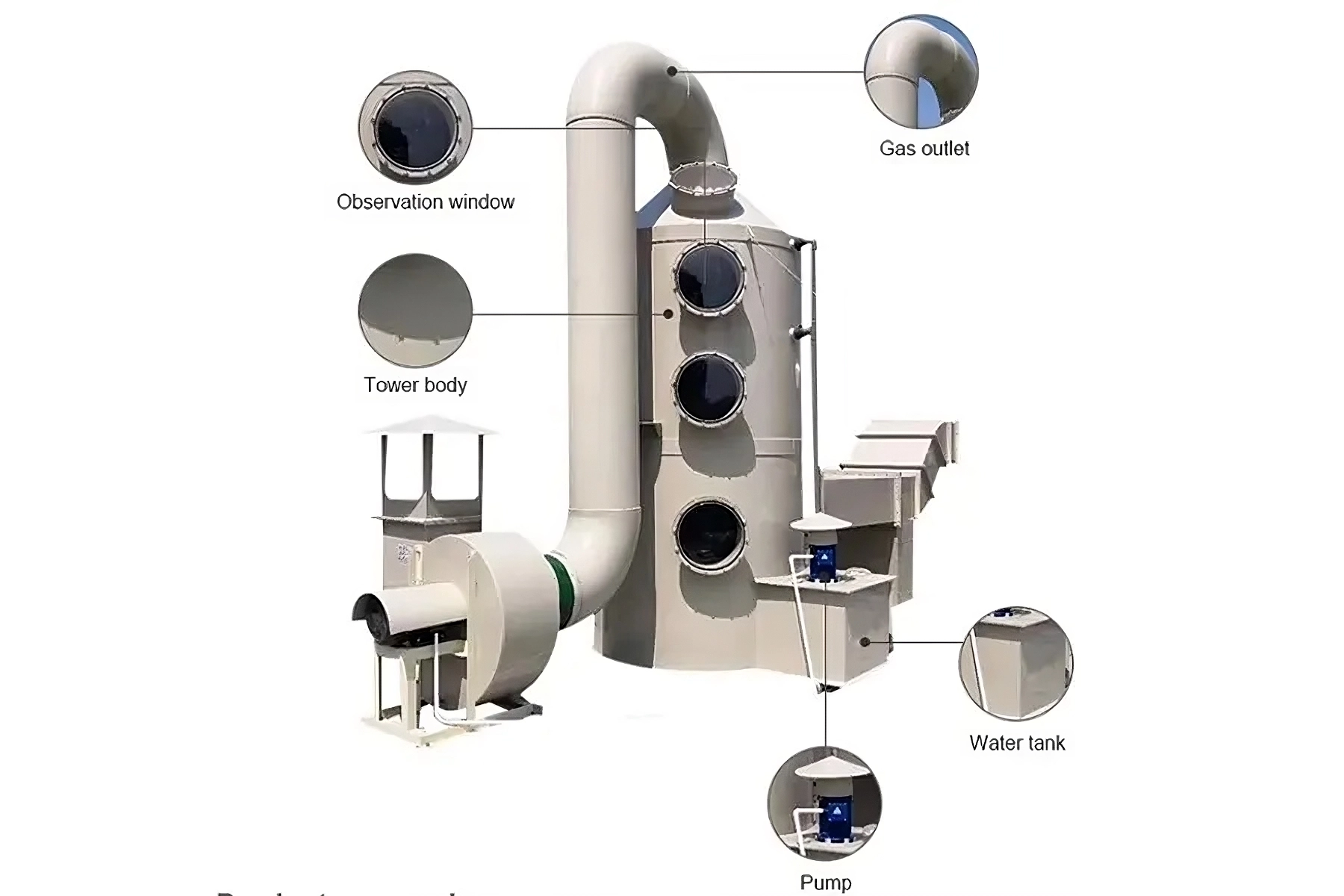

PICKLING PROCESS

ACE’s Scrubber achieves high efficiency in removing acid vapors (HCl, H₂SO₄, HNO₃), Cr⁶⁺ vapors, and other hazardous components, applying absorption–neutralization technology in specialized solutions. After treatment, the exhaust gas complies with National Technical Regulation QCVN 19:2024/BTNMT.

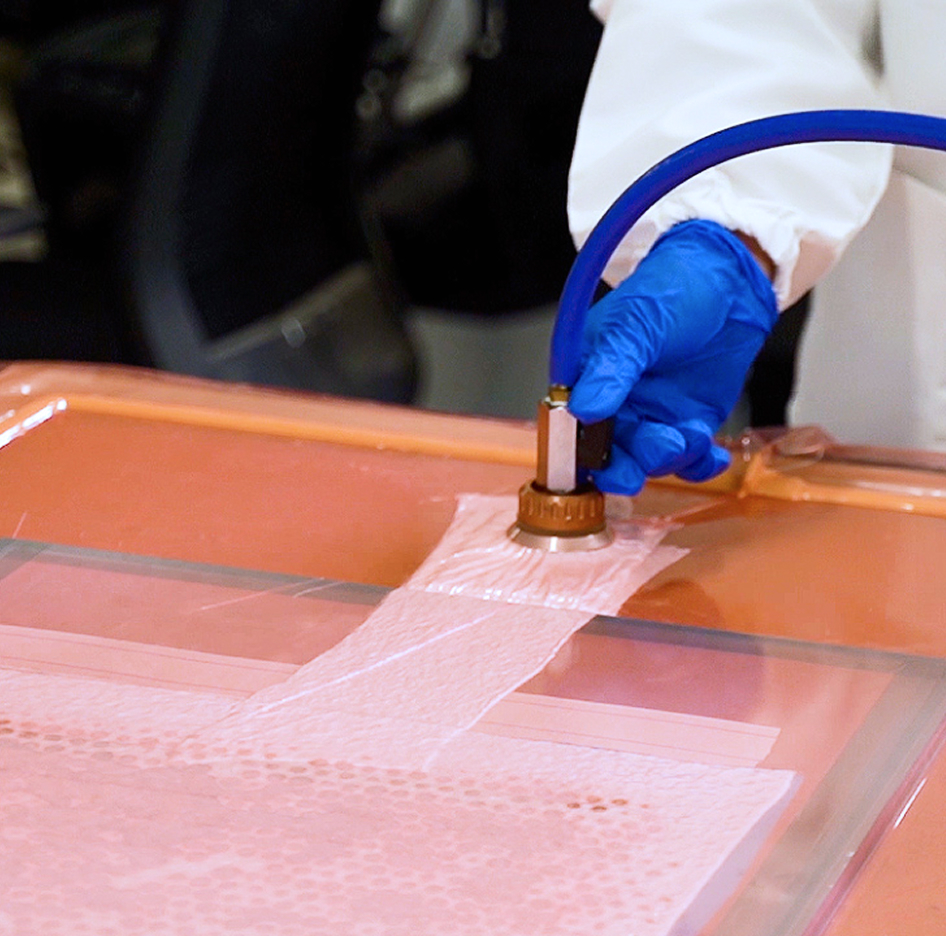

Picking Process

1

Collection of exhaust gas

Exhaust gases generated during the electroplating process are collected through hoods and ducts.

2

Introduction into the scrubber

The exhaust gas enters the scrubber to come into contact with the absorption–neutralization solution.

3

Removal of hazardous substances

Pollutants are captured, neutralized, or reduced in the specialized solution.

4

Moisture separation

The demister unit retains fine solution droplets, ensuring cleaner air.

5

Release of clean gas

After treatment, the exhaust gas meets the requirements of QCVN 19:2024/BTNMT.

Outstanding Advantages

Drag the mouse to view the 360° image

Image gallery

ĐĂNG KÝ TƯ VẤN

Liên hệ ACE Việt Nam để được tư vấn và cung cấp giải pháp tối ưu nhất!