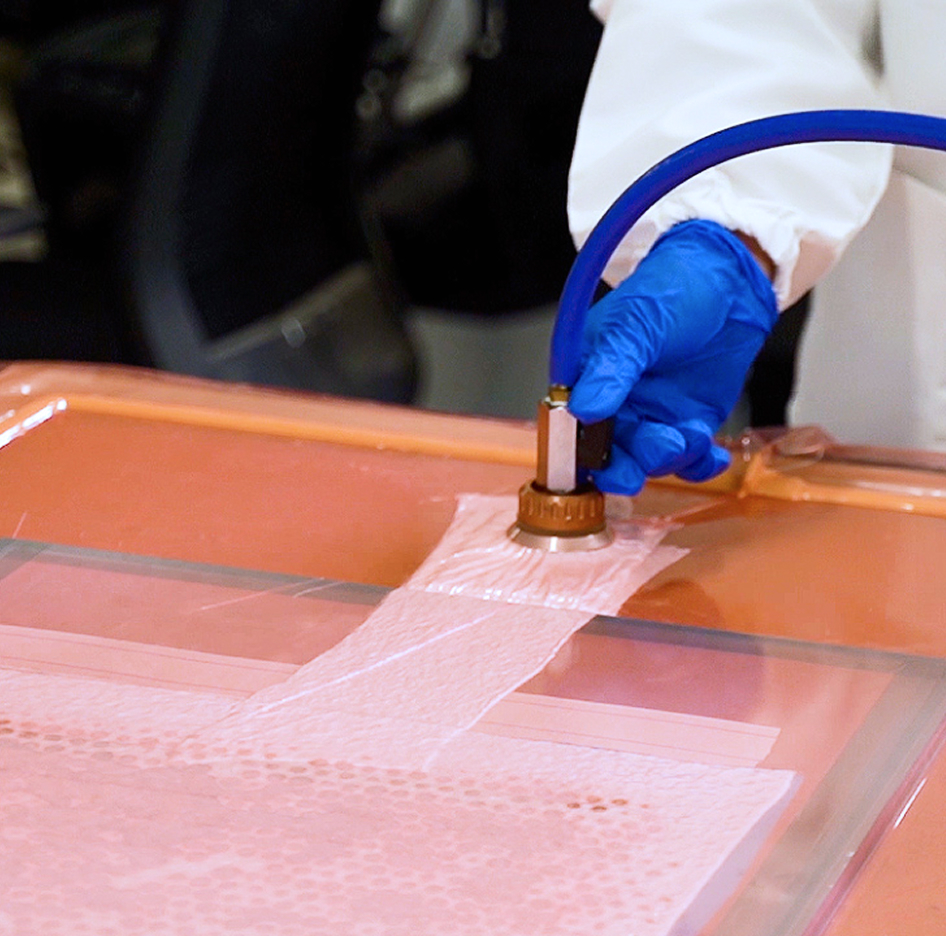

Battery Process

The most commonly wet-cell battery product uses lead-acid battery consists of a lead metal anode and lead oxide cathode, both of which are immersed in a solution of sulfuric acid that be caused to found air pollutants. Air pollution control system will prevents sulfuric acid, lead fumes the enviroment. We use scrubbers which are effective for removal under certain conditions. Wet scrubbing works via the contact the pollutants by scrubbing solution, pollutants are more soluble in the scrubber and can be captured.

Battery Process

1

Collection

Exhaust gas from the battery manufacturing process is collected and directed into the treatment system.

2

Absorption

The exhaust gas is introduced into the absorption tower, where it comes into contact with the absorbing solution. This process neutralizes pollutants, converting them into less harmful compounds.

3

Filtration and purification

After passing through the absorption tower, the exhaust gas flows through layers of packing materials to remove remaining dust and impurities.

4

Discharge of clean gas:

The exhaust gas, after being treated and purified, is discharged into the environment through the chimney, ensuring compliance with regulatory standards.

Outstanding Advantages

Drag the mouse to view the 360° image

Image gallery

REGISTER FOR CONSULTATION

Contact ACE Vietnam for consultation and the best solutions!